Finncont plastic semi underground waste containers are distinguished by an affordable price, ease of installation and maintenance, high environmental friendliness and reliability.

Currently, 250,000 of such containers are installed in the countries of northern and western Europe, some of which have already exceeded 25 years of service age.

Framing options: Plastic surface (standard), composite panels, perforated aluminum (clean or painted) or panels with customer advertisements.

Accessories: 70 liters Drum lid, which prevents penetration into the container, electric or mechanical lock: Abloy, iloq, Assa, Ruko, GPS alarm, fire extinguishing system.

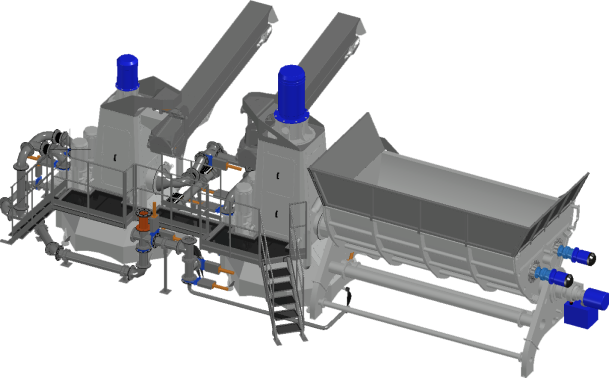

Press compressors НАВА are used to compact waste and minimize the costs of transportation.

Provide high efficiency when used in the waste management system at industrial enterprises, shopping centres, crowded areas, is an integral part of the equipment used at waste processing enterprises.

Operate autonomously in automatic or semi-automatic mode, transported by vehicles equipped with MULTILIFT demountable systems

НАВА compactors can be used for mixed waste or specific types of secondary raw materials.

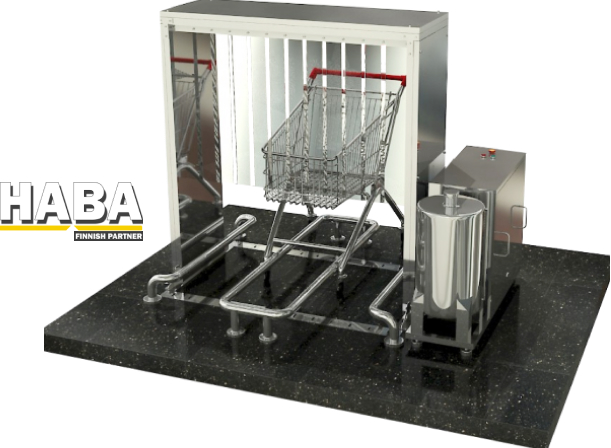

HABA SAFE is designed to disinfect surfaces from all types of viruses and bacteria. HABA SAFE equipment can be used, for example, in industrial premises, hospitals and public buildings.

There are also special frames for disinfecting shopping trolleys. Indeed, in our time, this issue is very relevant. The HABA SAFE shopping trolleys disinfection system is a simple, effective and fast way to kill bacteria and viruses.

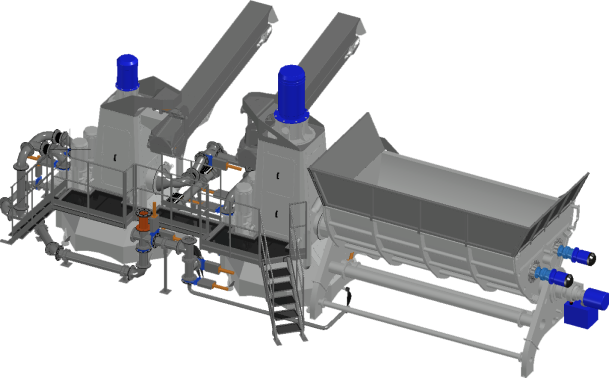

The unit is used on lines for domestic waste processing and is designed for automatic separation of prepared waste to obtain organic slurry and inorganic fragments.

Domestic waste is fed to a hopper with a screw crusher and processed in primary and secondary processing turbines.

The organic slurry mass is then used to generate biogas.

Fragments of inorganic origin are fed to separate lines for further processing or disposal (including automatic selection of scrap metal, production of combustible gas or liquid fuel, use in building materials and mixtures, etc.).

The pre-treatment system increases the gas pressure, removes water vapor and impurities from it, and with the use of latest membrane technology improves the bio-methane content of the biogas to a level comparable to natural gas. In the combined heat and power unit of AERIS, the energy of the upgraded bio-methane gas is turned into electricity and heat, and the excess gas can be temporarily stored or be compressed for automotive use.

Due to the modular architecture, the same hardware and software units can be used in different conditions and applications. The AERIS system can be complimented later on with additional Aeris units or solar or hydroelectric installations, thus creating a hybrid power plant capable of utilizing a plethora of renewable energy sources.

The Aeris concept harnesses unutilized resources, already in your possession.

We always start with a detailed analysis of your needs, factor in the initial data from the available volumes of biogas feedstock and calculate the efficiency of our equipment.

Following the modular design principles of Ophi Technologies Ltd, the necessary set of equipment in the basic configuration can be offered with a minimal initial investment, and new system elements can be added subsequently, depending on the financial capabilities of the customer, in case of an increase in the volume of processable raw materials, or an increased need for electrical and thermal energy.

The module is intended for use as an autonomous unit for generating heat energy with accompanying generation of electricity. It is effective for generating heat/electrical energy for detached industrial and/or residential townships, premises, buildings in the presence of constant reserves of wood chips.

Made in Finland, fully ready for connection and use, it is possible to optionally supply equipment for automatic wood chips supply to the reactor module.

Customer is responsible for further installation and assembly work needed on site, for example: building fuel conveyors, attaching electricity cables, heat channels, water lines, providing broadband + GSM-connection and a fuel silo.

Model: 40 kW (for indoor placement).

Dimensions of the unit: Length 4820mm, width 1270mm, height 2500mm.

Weight of the unit: approx. 4500kg

Contact us and we will definitely respond to you.

Contact you soon.